Noise Control to reduce Noise and Vibration

Mechanical and electrical machinery is a major source of loud noise and vibration in buildings. These machines generate vibration and causing the noise to the surrounding area and neighbour premise.

Contractors and building managers are responsible to resolve this problem thru reduction of noise by technical means according to:

Of course, it goes without saying that those who live or work in these buildings experience unwanted effects. They have a reduced quality of life because of the disturbance that these vibrations and noise cause. As a result, finding ways of overcoming the problem is imperative for property owners. Here at Acrefine, we have developed a number of efficient systems that minimise vibrations and noise significantly.

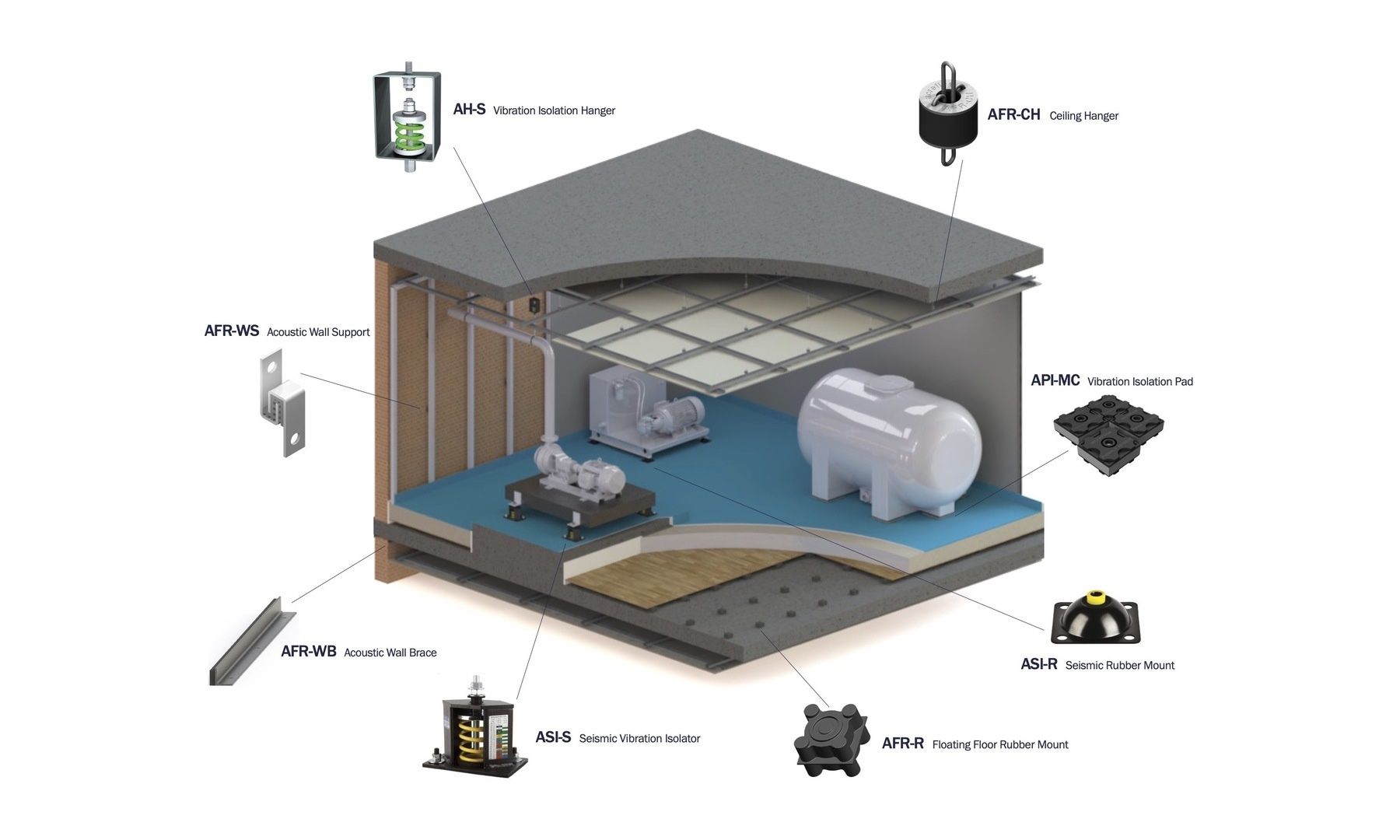

Floating systems are effective ways of overcoming the problem of excessive noise. These systems create an air gap in between the mechanical plant room and the primary structure itself. Resilient mounts create these gaps between the walls, ceiling, and floor.

The primary purpose of floating systems is to minimise noise transmission into surrounding areas. Floating rooms perform acoustically on a principle of the creation of an impedance mismatch. That means the transmission loss will be far greater than that with a continuous design. An excellent way to minimise noise nuisance.

Here, we take a closer look at the various components of floating rooms systems.

Floating Floors minimise industrial noise coming from noisy mechanical plant rooms

Floating floors are a common component of floating rooms systems. They’re also suitable for use alone if the primary concern is the transmission of sound to the rooms below.

A floating floor locate on the primary supporting floor slab. Usually, it is a rather thin level of reinforced concrete. It locates on plywood with supporting resilient mounts underneath.

Choosing the most appropriate mount and ensuring proper design are key factors in ensuring optimal sound isolation. The mounts’ natural frequency (Fn) will greatly determine the system’s performance level overall.

In practice, it’s possible to achieve a floating floor with an Fn of 15 Hz. That’s sufficiently low to have a significant impact. We manufacture special rubber mounts AFR-R type for use in standard applications. We also manufacture spring mounts for better performance, meaning no more noise complaint.

Acoustic Ceiling Hangers can be used for both domestic and work places

Vibration isolation or ceiling hangers create air gaps in between the noisy room and the ceiling above. Usually, the construction is a suspended frame that has gypsum boards fixed on to it. Floor mounted machines and piping installations sit directly on this structure.

Here at Acrefine, we manufacture special elastomer hangers for standard applications. For lower frequencies, we also have appropriate hangers available for any level of noise pollution.

The main 3 kinds of vibration hangers are elastomer hangers, spring hangers, and combination hangers. The primary difference between elastomer and spring hangers is springs have negligible damping but elastomer offers damping properties.

Spring-based isolators have a higher load range and greater deflection for better noise levels. As a result, they are more efficient at vibration isolation. For wide vibration ranges, combined hangers are the preferred choice.

Ceiling Hanger Types

A spring hanger has a coiled compression spring made from steel as its vibration isolation component. It provides deflections of 10-100mm and there are 2 types – housed and open spring hangers. An open spring hanger has one spring and a limited load capacity. Conversely, a housed hanger can have multiple springs in one housing, allowing for higher load capacities.

With rubber hangers, an elastomer compound moulded in a range of A Shore hardnesses achieves vibration isolation. The damping characteristics of these hangers are excellent, dissipating vibration energy effectively. These hangers are suitable for deflections up to 13mm.

An open rubber hanger has a single element with a limited load capacity. For higher load capacities and more stability, a housed hanger is suitable.

Meanwhile, a combined hanger provides the characteristics of both elastomer and spring vibration isolators. Our combination hangers minimise wide range of vibration from suspended services and equipment, hence providing excellent noise control. With welded steel housing, these hangers allow for more strain.

Sound Isolation Walls help eliminate noise problems

Isolated walls create acoustical air gaps on the walls of the isolated room. Their installation require special brackets. These feature elastomer elements for resilient mounting. We manufacture wall bracese and mounting brackets designed for use in the installation of floating walls.

By using these systems correctly and together, it’s possible to achieve a high level of acoustical performance.

However, acoustical performance will always depend on the system’s resilience. Therefore, all intersections with another surface or penetrations should allow free floating of the system without rigid connections.

Here at Acrefine, we understand the importance of effective noise control within a building. That is why we are dedicated to manufacturing only the highest quality noise control products. Whether you need an isolated wall, a floating floor, or ceiling hangers, we can help.

With our well-designed systems in place, it’s possible to effectively minimise noise transmission in your building. Whether in a domestic or commercial building, our solutions are perfect for significant vibration and noise reduction.