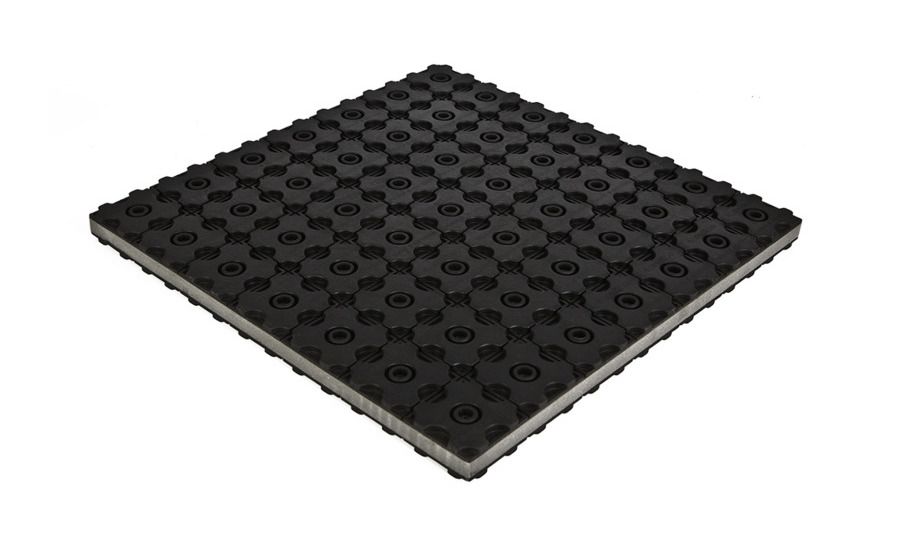

API-MC Modular Copolymer & Rubber Pad

Acrefine API-MC type rubber pad is designed to minimize vibration and noise transmission from floor mounted equipment. API-MC incorporates a sandwiched design where special copolymer material is laid between two layers of modular rubber. This special structure has elastomeric properties that outperform conventional materials such as cork and shredded rubber.

Pads are manufactured in 357×357 mm (14”x14”) size and can be cut to any combination of 50 mm (2”) dimension sizes. The standard thickness of the pad is 22 mm (7/8”). The design also allows for holes to be cut for any combination of modules (see figure below).

- Modular design with rubber and composite material

- Through bolt hole in each module for easy installation

- Fixing hole can be cut for any size and combination

- Can be easily cut with box knife to required size

- No need to stock pre-cut pads

- Can be stacked with steel plates to achieve higher deflection

- 22 mm (7/8”) thickness

- 63 kg (140 lb) load capacity per module

Acrefine API-MC type vibration isolators are suitable for floor mounted mechanical equipment that generates high frequency vibration, i.e., pumps, chillers, compressors, centrifugal fans, blower-coil units, vent sets, low pressure packaged air-handling units, etc.

API-MC type vibration isolation pads are available with up to 4.4 mm (3/16″) deflection and 63 kg (140 lb) load capacity for a single module. If higher deflections are required, the pads can be stacked with steel plates between layers.