Seismic Calculations for Equipment | Seismic Load Analysis

Three ways widely accepted in the MEP / HVAC industry for seismic protection are:

- Overturning Calculations

- Equipment Seismic Analysis

- Shake Table Testing

Overturning Calculations: Seismic calculation per equivalent lateral force procedure

ASCE 7 and other international building code and local codes require a seismic design for non-structural components.

The starting assumption is that the component is sturdy and would not collapse. Hence the primary concern is to secure the component to the structure. This minimises movement in the event of an earthquake. The anchorage calculation makes sure of transferring seismic loads to the structural element like a slab floor or ceiling.

First thing is to determine the magnitude of the design loads, then apply it in the worst direction possible. Then assume that it acts on the center of gravity of the component. Thus causing overturning that generates moment forces at the restraint points. Based on the restraint type and their ratings, they create tension and shear stress at the anchors.

Selecting the correct type and number of restraints to transfer the seismic forces without failure completes the restraint design. Depending on each project requirement our engineers also produce detailed installation drawings that promote correct installation.

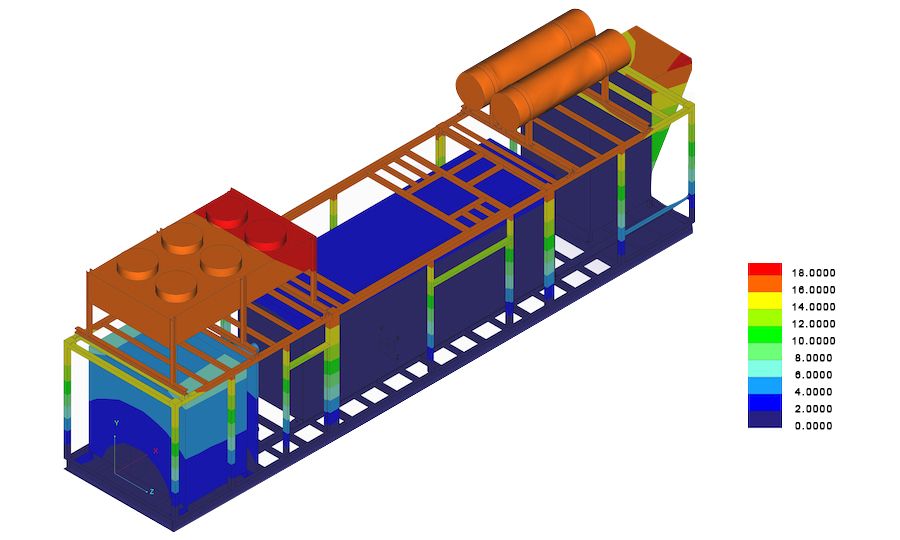

Equipment Seismic Analysis for certification objective

FEA (Finite Element Analysis) is a well known method to investigate the structural integrity of a component. The primary concern is to satisfy the mechanical strength criteria. With the aim to prove that components or sections of the component will not dismantle or fail, and it will remain as single piece.

To perform a seismic analysis, having a 3D model is the starting point. One can not perform an analysis without it. The 3D model is the input data, along with project specific seismic parameters. They are essential to determine the seismic forces.

Special analysis software is in action to perform the analysis, once all necessary input data are in place. Acrefine can help you qualify your product via analysis method. All you have to do is to supply the 3D model, along with your job specification.

The aim of seismic analysis is not to prove that the your product will be in fully functional state after the seismic event. For this aim, shake table testing is the only method.

Shake Table Testing for maximum safety

In some projects, the component is expected to be fully functional after a seismic event. These are typically mission-critical facilities like nuclear plants, data centres, and military bases. Sometimes qualification based on calculations and analysis is not adequate or acceptable. In these cases practical means come into play like a full-scale shake table testing.

These tests can be single axis or multi-axes. They simulate various past earthquakes or acceleration criteria set by building codes or project specifications.

There are only a handful of testing facilities around the world, where you can have your product tested. The challenges are the high costs and extremely long waiting times. Having said that, if you decide to have your product tested, Acrefine here can help you.

We offer consultancy services for shake table testing. Being a member below organisations, we have close relations with testing facilities in Europe.

- SECED (The UK’s Society for Earthquake and Civil Engineering Dynamics)

- SPONSE (The International Association for the Seismic Performance Of Non-Structural Elements)

Do I need Seismic Calculations?

Review your job specification carefully. If the project is in a seismic region, then most likely the answer is yes. We can help you determine these needs. Simply send us your job specification, and we will review it for you.

How much do Seismic Calculations cost?

It depends on your overall costs. In many cases, having a seismic certification pays off greatly in time. Contact us for a quotation.